Blog

“What does CNC stand for?”

The name “CNC” stands for Computer Numerical Control. CNC machining is a process using computer numerical control (CNC) machines. They can be the tools such as mills and lathes guided by computer instructions that control the instruments.

Subtractive manufacturing ...

The key to CNC Swiss turning is adding a bar feeder that spins the round bar and slides and feeds through the guide bushing in the Z-axis direction.

As a mini CNC Swiss lathe, the APSX-NANO has a max capacity of 20 inches long bar stock at a time. These machines provide stationary support fo...

3D printing has been an awesome way of creating products in recent years. We, as a company, used 3D printers to create prototypes from time to time. However, like any other current technology, 3D printing also has limits if your goal changes over time. For example, if you want to make more parts in ...

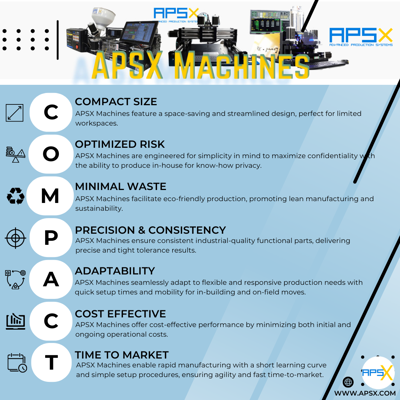

ADVANTAGES FOR INJECTION MOLDING

1 - Low scrap rates