3D Printing Service Bureaus

Injection Molding Solutions for 3D Printing Farms and Part Shops

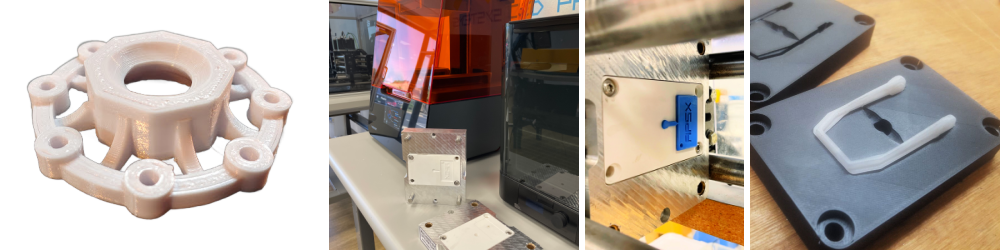

Bridge the Gap Between Prototyping and Production with APSX-PIM

APSX offers APSX-PIM, a compact injection molding machine, as the perfect complement to 3D printing farms and part shops. Whether you’re scaling up from prototypes to short-run production or looking to create final, market-ready products, the APSX-PIM empowers you to move beyond additive-only workflows. Enjoy rapid, cost-effective manufacturing while maintaining the flexibility you need for low-volume or custom parts.

Advantages of APSX Machines for 3D Printing Service Applications

- Compact, Plug-and-Play Design

The APSX-PIM’s small footprint easily fits alongside existing 3D printers or post-processing stations, minimizing space and setup requirements. - Short-Run & On-Demand Production

Ideal for bridging prototypes and final products. You can quickly create batches of identical parts without the high overhead of larger injection systems. - Versatile Material Options

From standard thermoplastics like ABS and PP to engineering-grade polymers, the APSX-PIM handles a range of resins for diverse project requirements. - Rapid Tooling & Mold Changes

Integrate 3D-printed molds or low-volume tooling to speed up development cycles. Swiftly adapt to design changes and new project demands. - Cost-Efficient Scaling

Eliminate outsourcing delays and costs. By combining additive manufacturing for prototyping with in-house injection molding, you maintain tighter control over quality and timelines.

Potential Applications & Specific Parts

- Functional End-Use Parts

Easily produce higher-volume orders of plastic components that began as 3D-printed prototypes—perfect for consumer goods, electronics housings, or specialized machinery. - Short-Run Batch Production

Manufacture small quantities of custom or niche items without the expense of large-scale mold setups, filling the gap between one-off prints and mass production. - Rapid Product Iteration

Seamlessly iterate on molds or part designs. Test, refine, and finalize your product faster than traditional injection molding lines allow. - Bridge Manufacturing

Use APSX-PIM to meet immediate demand or fill inventory while you finalize larger injection molds or plan for full-scale factory production.

Contact Us

Discover how the APSX-PIM injection molding machine can augment your 3D printing service bureaus, delivering cost savings, faster turnaround, and high-quality parts—all in-house. Let’s streamline your transition from prototyping to production, together!