Construction

Injection Molding Solutions for the Construction Industry

Build Better & Faster with Compact, Reliable Injection Molding

APSX’s small-footprint injection molding machines enable construction product designers and manufacturers to quickly produce durable, high-quality plastic components in-house. From prototyping innovative fixtures to low-volume production of specialty parts, APSX-PIM combines accuracy, flexibility, and cost savings to meet the evolving needs of modern construction projects.

Advantages of APSX Machines for Construction

- Rugged, High-Strength Parts

Mold components that stand up to harsh on-site conditions using engineered thermoplastics. - Rapid Prototyping & Short-Run Production

Quickly test new product designs or fulfill specialty orders without investing in large-scale equipment. - In-House Cost Control

Eliminate outsourcing and shorten lead times, keeping project budgets and timelines on track. - Compact & User-Friendly

Easily integrate APSX-PIM into small workshops or R&D labs, minimizing setup and training requirements. - Versatile Material Compatibility

Supports a range of resins suitable for construction applications, from UV-resistant plastics to flame-retardant materials..

Potential Applications & Specific Parts

- Fasteners & Anchors

Custom plastic anchors, clips, or connectors for various building materials. - Trim & Edge Protectors

Molding protective profiles or trims for windows, doors, and corners. - Pipe & Cable Management

Plastic brackets, clamps, or spacers to organize and secure essential utilities. - Custom Fixtures & Tooling

On-demand solutions for specialized construction tasks or one-off installations.

Contact Us

See how APSX-PIM can help you drive innovation, reduce costs, and deliver durable solutions for construction projects large and small. Get in touch today!

CNC Machining Solutions for the Construction Industry

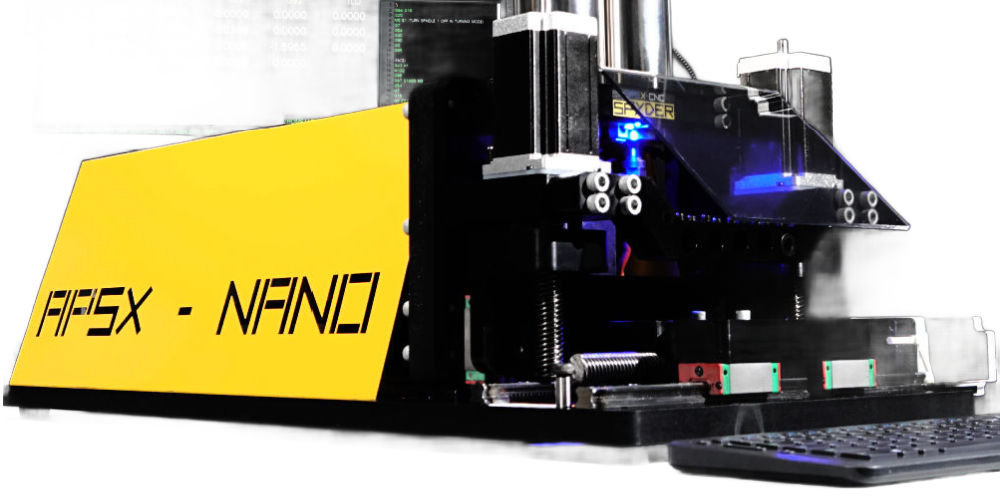

Build with Confidence Using Compact, High-Precision Swiss CNC Turning

APSX’s small-footprint Swiss CNC lathe, the APSX-NANO, equips construction product manufacturers and contractors with the ability to produce durable, high-accuracy metal parts in-house. Whether you’re developing specialized fasteners, bespoke fittings, or custom hardware, APSX-NANO delivers the precision and flexibility needed to excel in the construction sector.

Advantages of APSX-NANO for Construction

- High-Precision Machining

Create tight-tolerance components—ideal for structural connectors, custom anchors, and more. - Compact Footprint

Integrates easily into busy workshops or on-site fabrication centers, saving valuable space. - Cost-Effective Short Runs

Avoid large-scale manufacturing overhead by producing specialty parts on-demand for unique projects. - Robust Material Compatibility

Machine a variety of metals (e.g., stainless steel, brass, alloy steels) that stand up to the demanding conditions of construction. - Project Timelines

Reduce reliance on external suppliers and lead times by bringing critical fabrication steps in-house.

Potential Applications & Specific Parts

- Custom Fasteners & Anchors

Precision-turned bolts, nuts, and specialty anchors for secure, code-compliant installations. - Plumbing & Pipe Fittings

Durable metal couplings, valves, and adaptors that require leak-proof performance. - Decorative Metal Accents

Accent hardware that adds a premium touch to architectural designs. - On-Demand Repair & Replacement Parts

Rapidly produce small-batch or discontinued components to keep projects on schedule.

Contact Us

See how the APSX-NANO Swiss CNC lathe can help you streamline production, reduce costs, and deliver precision-crafted solutions for construction projects of every scale. Let’s build together!