Instrument Custom Parts

Injection Molding Solutions for the Music Industry

Shape Your Sound with Compact, Versatile Injection Molding

APSX’s small-footprint injection molding machine, the APSX-PIM, empowers luthiers, custom shops, and boutique instrument makers to easily produce high-quality plastic parts in-house. Whether you’re creating unique hardware, specialized components, or decorative elements, APSX-PIM offers the speed, flexibility, and cost savings essential for true craftsmanship.

Advantages of APSX Machines for Instrument Custom Part Applications

- Rapid Prototyping & Customization

Iterate quickly on new designs, refining knobs, pickup covers, or brackets to achieve the perfect feel and aesthetic. - Compact & Workshop-Friendly

Fits neatly into smaller production areas or personal studios—no large industrial space required. - Cost-Effective Small-Batch Runs

Ideal for limited-edition parts or custom orders without the overhead of large-scale tooling. - High-Quality Finishes

Consistent shot-to-shot molding ensures parts meet the precise standards demanded by discerning musicians and builders. - Versatile Material Options

Work with various plastics suited for instrument components—whether you need durability, unique textures, or specific coloration.

Potential Applications & Specific Parts

- Knobs & Controls

Customize the look and ergonomics of volume, tone, and other control knobs. - Pickup Covers & Housing

Mold distinctive shapes or add visual flair to your instrument’s electronics. - Bridge & Tailpiece Accessories

Create lightweight yet robust plastic parts where metal isn’t strictly necessary. - Decorative Accents

Achieve custom inlays or branded emblems to enhance a guitar’s or bass’s overall design.

Contact Us

Learn how APSX-PIM can streamline your design process, cut costs, and open up endless customization possibilities for your musical instruments. Let’s make music—together!

CNC Machining Solutions for the Music Industry

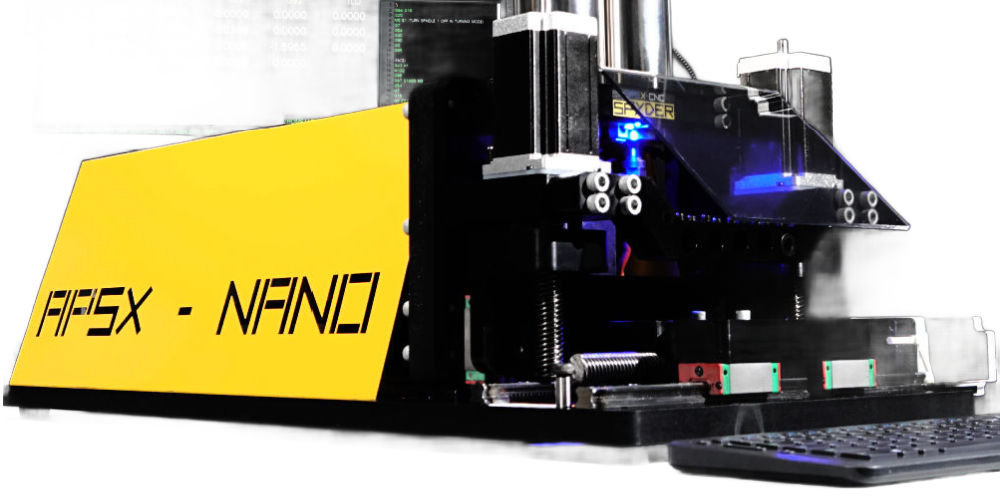

Strike the Perfect Note with Compact, High-Precision Swiss CNC Turning

APSX’s small-footprint Swiss CNC lathe, the APSX-NANO, empowers luthiers, instrument makers, and custom shops to craft intricate metal components in-house. From custom hardware and fittings to decorative inlays, APSX-NANO delivers the precision, consistency, and creative freedom needed to build truly unique, high-quality instruments.

Advantages of APSX-NANO for the Music Industry

- Exceptional Precision & Detail

Machine small or delicate parts—like tuning knobs, bridges, and tailpieces—with perfect repeatability. - Compact & Workshop-Friendly

Fits easily into a boutique instrument shop or home-based studio, saving space without sacrificing industrial-grade capability. - Cost-Effective Customization

Produce limited-edition hardware or specialized components without depending on expensive, large-scale facilities. - Wide Range of Metals

Use brass, stainless steel, or even exotic alloys to match your instrument’s aesthetic and acoustic requirements. - Rapid Prototyping & Iteration

Quickly test new design ideas and performance tweaks, refining your instruments on the fly.

Potential Applications & Specific Parts

- Tuning Pegs & Knobs

Craft beautiful, ergonomic, and durable tuning hardware for guitars, violins, or other stringed instruments. - Bridges & Tailpieces

Achieve perfect intonation and stability with precisely machined metal components. - Custom Endpins & Straps

Design unique metal fittings for string instruments, accommodating comfort and style preferences. - Decorative Inlays & Trim

Add personalized flourishes with engraved or intricately turned metal accents.

Contact Us

Find out how the APSX-NANO Swiss CNC lathe can help you create distinctive, high-quality instrument components that resonate with both sound and style. Let’s make music—together!