Military

Injection Molding Solutions for the Military and the Defense Industry

Rapid, On-Demand Manufacturing in the Field with APSX-PIM

The APSX-PIM injection molding machine brings high-performance, portable part production to defense contractors, military maintenance units, and specialized suppliers. Whether you’re making components for advanced weapon systems, protective gear, or communication equipment, the APSX-PIM’s compact design, field-ready mobility, and fast cycle times give you unparalleled control over part manufacturing—securely, efficiently, and on location whenever duty calls

Advantages of APSX Machines for Defense and Military Applications

- Robust Injection Molding in a Compact Footprint

Designed for easy relocation, APSX-PIM can be deployed to different bases or field sites with minimal setup, ensuring parts are produced where and when they’re needed. - Secure In-House Production

Keep sensitive designs classified by eliminating the need for external vendors. Maintain control of IP, reduce supply chain risks, and ensure the highest level of confidentiality. - Broad Material Compatibility

Mold high-grade, impact-resistant polymers (like nylon, polycarbonate, or specialty military formulations) and also metal parts (Metal Injection Molding MIM) to meet rigorous durability and performance standards. - Rapid, On-Demand Manufacturing

Swiftly produce critical components for vehicle maintenance, personal equipment, or mission-specific gear, reducing downtime and accelerating operational readiness. - Cost-Effective Short Runs & Prototyping

Create pilot batches or one-off custom parts without incurring the expense and delays of large-scale injection molding operations—perfect for field repairs and urgent tasks.

Potential Applications & Specific Parts

- Weapon System Accessories

Mold grips, housings, or covers that meet strict size and durability requirements for weapons used in diverse climates and conditions. - Protective Gear Components

Produce rugged helmet liners, padding, or armor inserts that can be quickly adapted to ever-changing field needs. - Communication Device Enclosures

Lightweight, shock-resistant housings to protect sensitive electronics, ensuring reliable performance in hostile or remote environments. - Field Repair Kits & Replacement Parts

Leverage the APSX-PIM’s portability to quickly address unexpected breakages or maintenance issues—keeping mission-critical equipment operational.

Contact Us

Discover how the APSX-PIM injection molding machine can empower defense and military units with mobile, on-demand production. From field repairs to secure in-house prototyping, stay mission-ready—anywhere, anytime.

CNC Machining Solutions for the Military and the Defense Industry

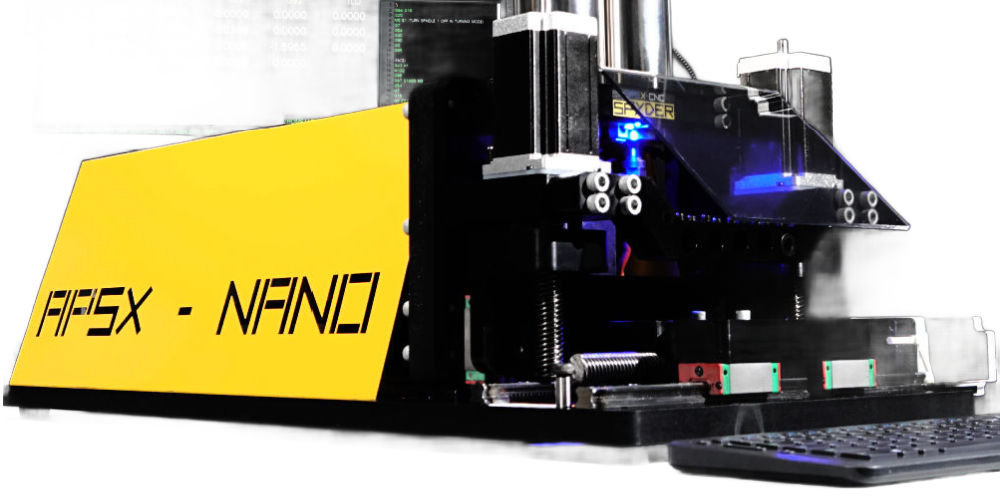

Enhance Mission-Critical Manufacturing On-Demand with APSX-NANO Swiss CNC

The APSX-NANO delivers uncompromising precision, reliability, and portability for defense contractors, military maintenance facilities, and specialized suppliers. Whether you’re fabricating components for advanced weapon systems, armored vehicles, or communication devices, the APSX-NANO’s compact design, mobile-friendly setup, and high-accuracy machining give you full control over part production—securely, efficiently, and on location.

Advantages of APSX-NANO for Defense & Military

- High Precision & Tight Tolerances

Critical for safety and performance in defense applications, the APSX-NANO provides the accuracy required for mission-critical components. - Robust, Compact Footprint & Mobility

The machine’s small size and relatively low weight make it straightforward to relocate to different field bases or deployment areas, minimizing logistical challenges. - Secure In-House Production

Maintain confidentiality and control over sensitive designs or classified projects by eliminating the need for external machine shops. - Wide Material Compatibility

Machine high-strength metals—such as stainless steel, titanium, or specialized alloys—vital for military-grade durability and longevity. - Rapid, On-Demand Part Making

Quickly produce small quantities or custom parts for field repairs, equipment upgrades, or urgent operational requirements—ideal for expeditionary forces.

Potential Applications & Specific Parts

- Weapon System Components

Precision-machined parts for firearms, turret assemblies, missile guidance systems, or other advanced weapon platforms. - Armored Vehicle Hardware

Critical fittings, brackets, or structural reinforcements required to withstand extreme environments and impacts. - Communication Device Housings

Durable, lightweight enclosures designed to protect sensitive electronics in harsh or remote deployment scenarios. - Custom Fixtures & Field Repair Tools

Specialized jigs or replacement parts for rapid turnaround and on-site repairs, drastically reducing equipment downtime.

Contact Us

Discover how the APSX-NANO Swiss CNC lathe can streamline production, maintain stringent security, and ensure dependable quality—even on the move. Enhance mobility, reduce downtime, and stay mission-ready—anywhere, anytime.