Education

Injection Molding Solutions for the Educational Institutions

Empower Future Innovators with Hands-On Injection Molding Experience

APSX’s compact injection molding machines offer an accessible, industry-relevant platform for students, educators, and researchers. By integrating real-world manufacturing processes into the classroom or lab, APSX-PIM enriches STEM, engineering, design, and vocational training programs, helping prepare the next generation of innovators.

Advantages of APSX Machines

- Hands-On Learning

Give students tangible, practical experience with modern manufacturing equipment—bridging the gap between theory and industry practice. - Safe & User-Friendly

Compact design with straightforward controls, making it suitable for classroom or lab environments where safety and ease-of-use are priorities. - Cost-Effective

Lower investment than large industrial machines, enabling more institutions to integrate injection molding into their curricula or research facilities. - Rapid Prototyping & Experimentation

Students can quickly design, test, and iterate parts, fostering creativity and problem-solving skills. - Versatile Material Options

Explore a wide range of plastics—ideal for teaching material science, polymer chemistry, or engineering applications such as ASTM test specimens.

Potential Applications & Specific Parts

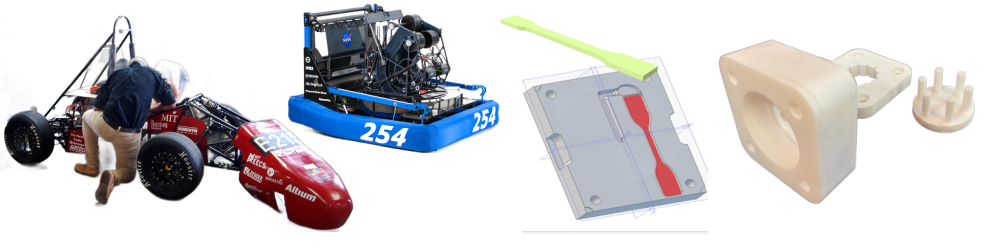

- STEM Education and FRC Robotics Projects

Design and mold functional prototypes for engineering competitions, FRC robotics teams, Formula SAE teams or capstone projects. - Technical Training

Familiarize students with real-world injection molding processes, preparing them for immediate job readiness in manufacturing sectors. - Research & Development/strong>

Conduct materials ASTM testing or process optimization studies for undergraduate and graduate research. - Product Design & Entrepreneurship

Encourage innovation and business-minded thinking by allowing students to create and market small-batch products. Schools and technical programs can demonstrate the entire cycle—design, 3D-print tooling, and produce a molded part. It’s an excellent, budget-friendly approach to teaching the fundamentals of injection molding and product development.

Contact Us

Discover how APSX-PIM can transform your classrooms, labs, or vocational training centers, providing hands-on industry experience and sparking innovation. Let’s prepare the next generation of skilled professionals—together!

CNC Machining Solutions for the Educational Institutions

Empower the Next Generation of Innovators with Compact, High-Precision CNC Turning

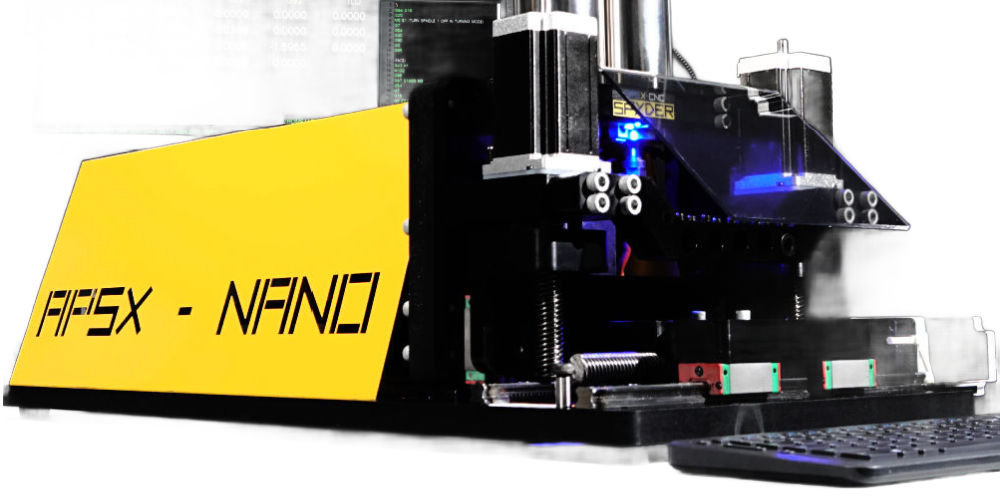

APSX’s small-footprint Swiss CNC lathe, the APSX-NANO, brings real-world machining experience to classrooms and labs, equipping students and trainees with the skills needed for modern manufacturing. From basic CNC fundamentals to advanced prototype fabrication, APSX-NANO delivers hands-on learning opportunities in a safe, user-friendly format.

Advantages of APSX-NANO

- Compact & Classroom-Friendly

Minimal space requirements and straightforward operation, ideal for tech labs, vocational schools, and university engineering departments. - Hands-On Learning

Students gain practical machining experience, bridging the gap between theoretical study and real-world industry practices. - Cost-Effective Solution

Lower investment than traditional large-scale CNC equipment, enabling more institutions to integrate advanced manufacturing into their curricula. - Industry-Relevant Skills

Swiss CNC turning is widely used in high-precision manufacturing, giving graduates a competitive edge in the job market. - Versatile Application

Machine various metals, from aluminum to stainless steel, demonstrating fundamental principles of CNC setup, tooling, and process control.

Potential Applications & Specific Parts

- Student Projects & Competitions

Fabricate custom parts for FRC robotics and Formula SAE teams, engineering contests, or design-build challenges. - Workforce Development & Certification

Train apprentices or re-skill workers on advanced CNC operations, preparing them for immediate employment in modern shops. - Research & Prototyping

Support academic research by producing components for experimental setups, lab instruments, or test fixtures. - Teaching Aids & Demonstrations

Illustrate machining principles, toolpath programming, and tooling selection with real, hands-on examples.

Contact Us

Discover how the APSX-NANO Swiss CNC lathe can enrich your curriculum, equip students with sought-after skills, and foster the next wave of manufacturing innovation. Let’s shape a brighter future—together!