Applications

APSX Machines: Compact footprint, exceptional value

.

|

|

|

||

Affordable |

Sustainable |

Innovative |

||

| APSX Machines deliver high performance at affordable prices, empowering businesses to easily innovate and quickly scale without compromising reliability, or cost. They are available today. | APSX Machines emphasize eco-friendly operation, reducing waste and energy use to minimize environmental impact—ensuring sustainability without compromising reliability or performance. | APSX Machines offer innovative machines and advanced features to foster innovation, enabling you to rapidly prototype, produce parts, and stay ahead in an your market. They are one of a kind. |

.

Explore specific applications and discover the benefits of APSX machines in your industry by clicking on the industries listed below.

.

|

Precision and repeatability are key in the automotive sector for components like clips, fasteners, and interior features. |

||

|

From rapid prototyping to short-run production, APSX Machines deliver the agility, accuracy, and cost savings vital to stay ahead in the ever-evolving electronics market. |

||

|

APSX’s small-footprint machines are ideal for producing high-precision components in medical and dental applications. |

||

|

Whether you’re making components for advanced weapon systems, protective gear, or communication equipment, compact design, field-ready mobility of the APSX Machines give you unparalleled control over part manufacturing. |

||

|

Lightweight materials, intricate geometries, and tight tolerances are easily managed, opening doors to advanced component manufacturing. Such as POWER (METAL) INJECTION MOLDING (MIM) for small turbine blades. |

||

|

From prototyping innovative fixtures to low-volume production of specialty parts, APSX combines accuracy, flexibility, and cost savings to meet the evolving needs of modern construction projects. |

||

|

Score Big with Compact, High-Performance Injection Molding and CNC machining. |

||

|

APSX Machines can enrich your curriculum, equip students with sought-after skills, and foster the next wave of manufacturing innovation. |

||

|

Whether you’re scaling up from prototypes to short-run production or looking to create final, market-ready products, the APSX empowers you to move beyond additive-only workflows. |

||

|

Whether you’re finalizing client prototypes, refining designs for low-volume production, or testing new market ideas, APSX empowers you to manage design iterations in-house—speeding up timelines and enhancing creative control. |

||

|

From personalized gadgets to large production runs, our flexible and cost-efficient systems adapt to a wide array of consumer product needs. Such as BIOPLASTICS as disposable cups or keychains. |

Specific Applications

|

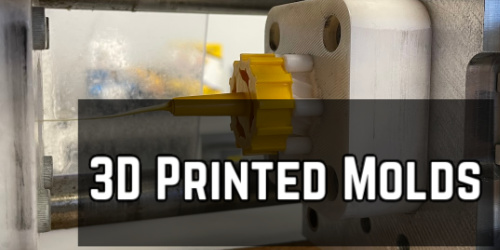

3D printed molds offer a compelling alternative for injection molding applications, particularly for prototyping and low-volume production. |

||

|

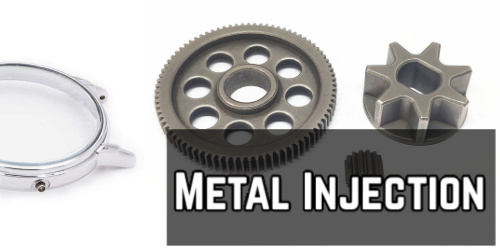

Metal (Powder) Injection Molding (MIM) is an advanced manufacturing process that combines the versatility of plastic injection molding with the material strength of powdered metals and ceramics. |

||

|

APSX’s small-footprint machines allow firearms designers, manufacturers, and gunsmiths to produce plastic and, with specialized PIM/MIM processes, certain metal components in-house. |

||

|

APSX’s small-footprint Swiss CNC lathe, the APSX-NANO, offers knife makers the ability to produce high-quality, custom metal components in-house. |

||

|

Whether you’re creating unique hardware, specialized components, or decorative elements, APSX offers the speed, flexibility, and cost savings essential for true craftsmanship. |