Sports Gear

Injection Molding Solutions for the Sports Gear Industry

Score Big with Compact, High-Performance Injection Molding

APSX’s small-footprint injection molding machines empower sports equipment designers and manufacturers to produce durable, high-precision components in-house. From rapid prototyping of next-generation gear to low-volume production of specialty parts, the APSX-PIM helps you stay competitive in a market where innovation and quality are everything.

Advantages of APSX Machines for Sports Gear Applications

- Rapid Prototyping & Design Iteration

Quickly test and refine new product concepts to bring performance-enhancing gear to market faster. - In-House Cost Control

Eliminate outsourcing expenses and reduce lead times by molding smaller runs of parts on-demand. - Consistent, High-Quality Parts

Ensure every component—from handles to protective gear—meets the rigorous demands of athletic performance. - Compact & User-Friendly

Easily fit the APSX-PIM into design labs or small production floors, with minimal training required. - Versatile Material Options

Mold a range of thermoplastics suited for impact resistance, grip comfort, and lightweight performance.

Potential Applications & Specific Parts

- Protective Gear Components

Pads, inserts, or shells that require impact resistance and precise fit. - Handles & Grips

High-traction components for rackets, bats, or fitness equipment that enhance user comfort and control. - Cleats & Studs

Durable shoe components that can be easily swapped out or customized for different field conditions. - Custom Accessories & Training Aids

Specialized items for sports drills, coaching tools, or limited-edition product runs. Some athletic gear or accessories (custom grips, protective inserts) require short production runs or frequent design tweaks. 3D-printed mold options lower the risk and cost of experimenting with new designs.

Contact Us

Find out how APSX-PIM can help you bring innovative, high-performance sports products to market faster and more cost-effectively. Let’s transform the game—together!

CNC Machining Solutions for the Sports Gear Industry

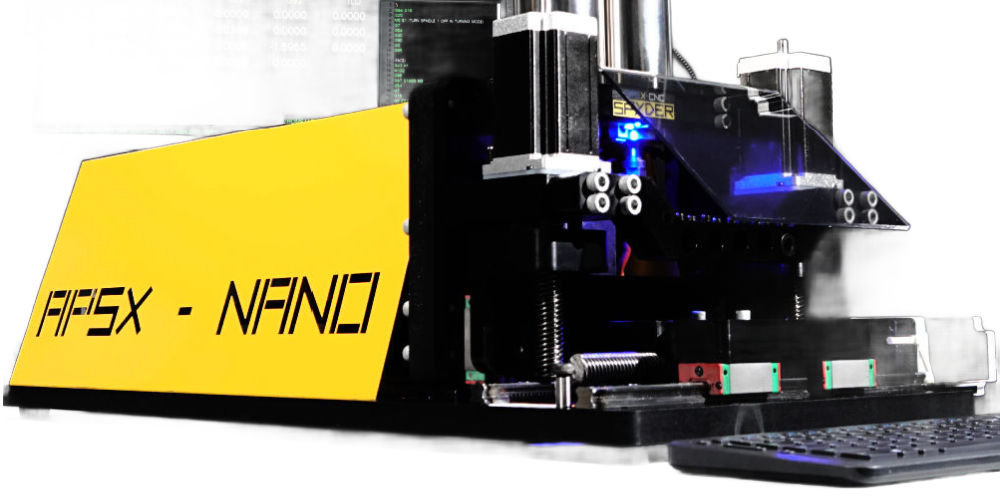

Elevate Performance with Compact, High-Precision Swiss CNC Turning

APSX’s small-footprint Swiss CNC lathe, the APSX-NANO, empowers sports equipment designers and manufacturers to produce intricate, high-strength metal components in-house. Whether you’re creating new prototypes, customized parts for elite athletes, or low-volume specialty items, APSX-NANO delivers the precision and efficiency you need to excel in a competitive market.

Advantages of APSX-NANO for Sports Gear Industry

- High-Accuracy Machining

Achieve consistent, tight tolerances—critical for performance-focused components like shafts, fittings, and adjustment mechanisms. - Compact & Versatile

Integrates easily into R&D labs or manufacturing floors, allowing for rapid experimentation and quick turnarounds. - Cost-Effective Low-Volume Runs

Perfect for limited-edition gear, custom orders, or advanced prototyping without large-scale investment. - Durable Material Compatibility

Machine high-strength metals (e.g., titanium, stainless steel) suitable for demanding, high-impact sports applications. - Streamlined Product Development

Bring design, testing, and production under one roof to speed up innovation cycles and maintain strict quality control.

Potential Applications & Specific Parts

- Cycling Equipment Parts

High-strength, lightweight components such as brake line fittings to enhance performance and stability. - Adjustable Fasteners & Fittings

Custom locking mechanisms or brackets for fitness equipment or specialized sports gear. - Protective Gear Hardware

Machined metal inserts, connectors, or pivots that offer robust protection in high-impact scenarios. - Custom Accessories & Mounts

Tailor-made parts for sports cameras, training aids, or gear add-ons, meeting niche athlete requirements.

Contact Us

Discover how the APSX-NANO Swiss CNC lathe can help you innovate, reduce costs, and bring world-class sports products to the market faster. Let’s champion high performance—together!