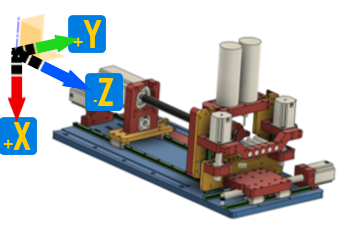

The key to CNC Swiss turning is adding a bar feeder that spins the round bar and slides and feeds through the guide bushing in the Z-axis direction.

As a mini CNC Swiss lathe, the APSX-NANO has a max capacity of 20 inches long bar stock at a time. These machines provide stationary support for the workpiece while the part is machined. This design enables the machine to hold tight tolerances and produce parts back to back. 5 axis Swiss-type machines have milling and drilling capabilities.

WHEN to Use a Swiss Type Lathe

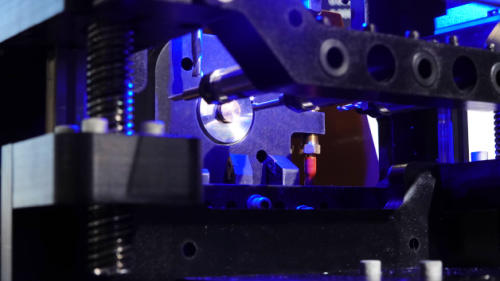

It is best when parts have milled and turned features that require precision machining. Swiss CNC machining allows for many milled features (flats, hex edges, slots, left hand threading etc.) to be produced during the turning process without the need for multiple setups on additional equipment, providing greater production efficiencies with one process.

The rotary broaching process can be performed on these machines to cut standard or custom shapes into or onto a workpiece.

The ID centered rigid tapping or thread milling processes can be performed on the APSX-NANO CNC Swiss. You can also thread milling by using the live tools. There are multiple Swiss tooling companies that you can find a perfect tool for each application.

When smaller, more complex parts are needed. Typically, those parts are non-standard parts and can not be sourced directly. Examples would be tamper proof bolts, special nuts, pins, custom mechanical parts, nozzle inserts, pick and place tips, antique jewelry and watch parts, gunsmith parts, custom knives, custom musical instrument bolts and screws, fasteners, rc car and drone parts. Especially the screws (standard or custom) made out of Titanium (Grade 5) are expensive to buy. You can make them yourself by using the APSX-NANO CNC Swiss Lathe in house to save money and also make money by selling them.

Most of the Swiss-type parts are less than 1” (25mm) in diameter, with the majority being less than ¾” (16 mm) in diameter.

WHICH Industries?

Aerospace, automotive, drones, firearms (small arms and ammunition) and electronics components with multiple applications.

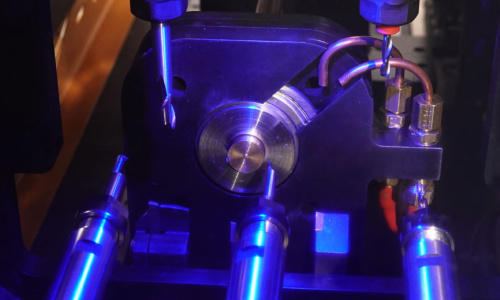

Medical and orthopedics: Bone screws, anterior cervical plates, fracture components, bone drills, surgical taps, orthopedic devices, surgical instruments, bone shavers and more.

Dental: Titanium implants, dental taps and drills, abutments and locking screws, dental driver instruments, orthodontic components and more.

Minimally invasive surgery: Screws, plates, housings, distal tips, cones, connecting rods, pins, grippers, surgical drivers and more.

Military vehicles and aviation: Cargo handling systems, guided missile, fuel systems, cockpit instrumentation, seatbelt mechanisms, cabin pressure control, wing flap actuation, antenna control, drones and more.