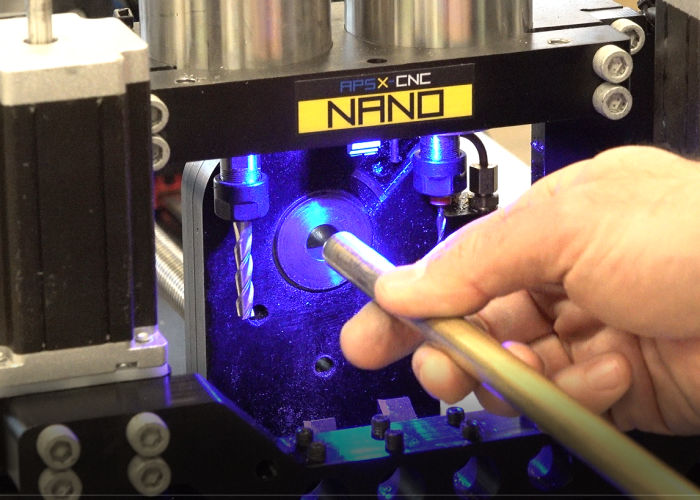

User guide for workpiece loading on the APSX-NANO

|

| -Click to Go Back |

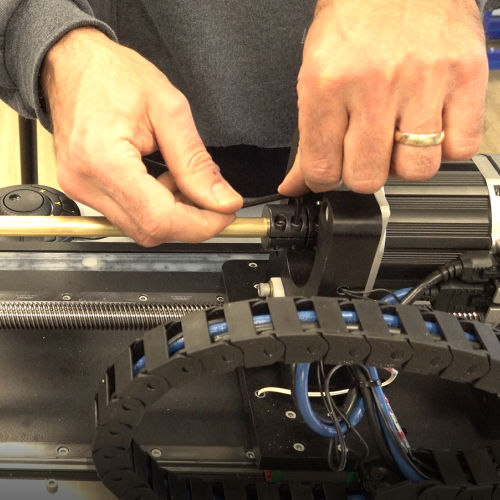

Loosen the setscrews on the guide bushing first.

APSX-NANO can machine a variety of materials. Here are some examples: Aluminum, bronze, copper, brass, stainless steel, titanium, and plastics such as Delrin, peek, polyetherimide (PEI) and polycarbonate.

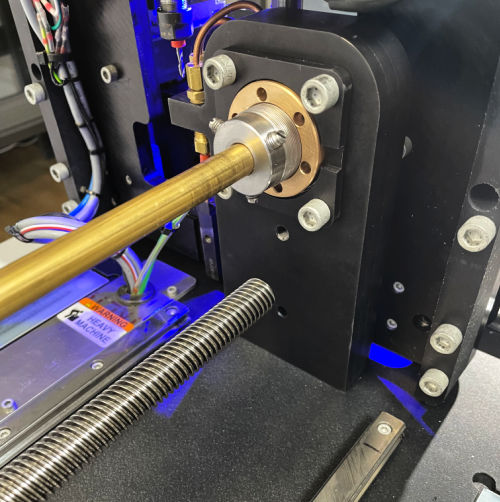

The bar stocks should be precision ground with tight diameter and straightness tolerance. Precision ground bar diameter tolerance -0.0005"-0” required. Straightness Tolerance 0.01" per ft. suggested. Max bar length to install: 20” (Machinable length: 17”)

Slide the workpiece through the guide from the front side of the machine. You can also use the other side of the guide bushing when you load a shorter bar stock.

APSX-NANO has the main spindle with a shaft coupling to mount the workpiece. Tighten the two setscrews on the coupling, then do only the snug fit on the three setscrews on the guide bushing. The bar stock should be able to slide through but also should be able to rotate the guide bushing.