In the complex world of manufacturing, precision and accuracy are paramount. Tolerances play a crucial role in ensuring that parts fit together correctly and function as intended. Whether you are a seasoned manufacturing manager or new to the field, understanding the role of tolerances in product design and machining is essential for optimizing your processes and achieving high-quality results.

The Importance of Precision in Manufacturing

Precision machining is at the heart of modern manufacturing. It involves the use of advanced equipment and techniques to produce parts that meet exact specifications. The goal is to create components that not only fit together seamlessly but also perform reliably under various conditions.

What Are Tolerances?

In the context of product design and machining, tolerances refer to the permissible limits of variation in a physical dimension. These variations can occur due to factors such as material properties, machining processes, and environmental conditions. Tolerances ensure that even with these variations, the parts will still function correctly and fit together as intended.

Types of Tolerances

There are several types of tolerances that designers and machinists must consider:

- Dimensional Tolerances: These specify the allowable variation in the dimensions of a part. For example, a shaft may be specified as 50 mm ± 0.02 mm, meaning the actual diameter can vary between 49.98 mm and 50.02 mm.

- Geometric Tolerances: These control the shape, orientation, and position of features on a part. Examples include flatness, cylindricity, and perpendicularity.

- Surface Finish Tolerances: These define the acceptable roughness or smoothness of a surface. Surface finish can impact the performance, appearance, and wear characteristics of a part.

The Role of Tolerances in Product Design

In product design, tolerances are integral to ensuring that parts can be manufactured consistently and perform as intended. Designers must balance the need for precision with the practicalities of manufacturing capabilities and costs.

Balancing Precision and Cost

Achieving tighter tolerances often requires more advanced equipment, longer machining times, and higher costs. Therefore, it's crucial to determine the appropriate level of precision for each part based on its function and the overall assembly. Overly tight tolerances can lead to unnecessary expenses, while too loose tolerances can result in parts that don't fit or function properly.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is a design approach that considers the manufacturing process during the design phase. By incorporating DFM principles, designers can create parts that are easier and more cost-effective to produce while still meeting the required tolerances. This involves selecting appropriate materials, designing for efficient machining, and specifying tolerances that align with the capabilities of the manufacturing equipment.

The Impact of Tolerances on Machining

Machining is the process of removing material from a workpiece to achieve the desired shape and dimensions. Tolerances play a significant role in determining the machining process, equipment selection, and quality control measures.

Equipment and Technology

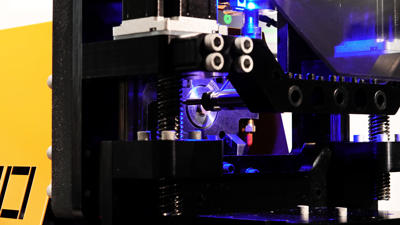

The choice of machining equipment and technology has a direct impact on the achievable tolerances. Advanced CNC (Computer Numerical Control) machines, such as those offered by APSX Machines, are capable of producing highly precise parts with tight tolerances. These machines use computer-controlled movements to achieve consistent and accurate results, making them ideal for high-precision applications.

Quality Control and Inspection

To ensure that machined parts meet the specified tolerances, rigorous quality control and inspection processes are essential. This includes using precision measuring tools, such as calipers, micrometers, and coordinate measuring machines (CMMs), to verify the dimensions and geometric features of the parts. Regular calibration of equipment and adherence to quality standards are also critical to maintaining accuracy and consistency.

Machining Knowledge and Expertise

Experienced machinists and engineers bring invaluable knowledge to the table when it comes to achieving precise tolerances. Their understanding of material properties, machining techniques, and equipment capabilities allows them to optimize the process and troubleshoot any issues that arise. Continuous training and staying up-to-date with the latest advancements in machining technology are essential for maintaining high standards of precision.

Practical Applications and Examples

Understanding tolerances and their impact on product design and machining is not just theoretical; it has practical implications for various industries. Here are a few examples:

Aerospace Industry

In the aerospace industry, precision and reliability are critical. Components such as turbine blades, landing gear, and structural elements must meet strict tolerances to ensure safety and performance. Advanced machining techniques and rigorous quality control measures are employed to achieve the required precision.

Medical Devices

Medical devices, such as surgical instruments and implants, require high levels of precision to ensure proper functionality and patient safety. Tolerances play a key role in the design and manufacturing of these devices, with stringent quality standards in place to verify compliance.

Automotive Manufacturing

In automotive manufacturing, tolerances are essential for ensuring that engine components, transmission parts, and other critical elements fit together correctly and function reliably. Achieving consistent tolerances helps improve the performance and longevity of vehicles.

Conclusion

Tolerances are a fundamental aspect of product design and machining that impact the quality, performance, and cost of manufactured parts. By understanding the role of tolerances and implementing best practices in design and machining processes, manufacturing managers can optimize productivity and efficiency while delivering high-quality products.

Embrace precision machining and leverage advanced equipment like APSX Machines to achieve the desired tolerances and elevate your manufacturing operations. Stay informed, invest in the right technology, and continuously improve your processes to remain competitive in today's demanding market.

Take the next step in optimizing your manufacturing processes by understanding and implementing the principles of tolerances in product design and machining.

#apsxmachines #precisionmachining #productdesign #designformanufacturability #apsxnano #swisslathe #swisscnc #cncmachining #producttolerance