Unboxing the Spyder CNC Machine

|

| -Click to Go Back |

You will receive the Spyder CNC in a wood crate with a truck delivery. It is about 285 lbs and 41" X 32" X 24" box.

The start up process is very simple: Open the crate, place the Spyder CNC on a desk or stand, plug and start using.

Content of the crate:

- SPYDER CNC Machine

- The embedded computer inside the control panel - no laptop or PC is required

- Keyboard Monitor with wall mount kit

- Control pendant

- SPYDER CNC software (installed)

- 1/4" endmill and ER11 collet

- Setup jig

- Wall-mountable plastic container for the coolant liquid

If you ordered the optional 4th axis, the machine comes with the 4th axis installed.

There is also an optional enclosure that can be used with the Spyder CNC. It comes as a separate shipment.

1 - Open the top of the crate

The machine is mounted to the crate. Put the other items aside before you start unscrewing the machine mounting screws. Remove the keyboard, monitor and mounting kit, endmill and collet, setup jig, and coolant container.

The control panel is bolted to the base of the machine. Spyder CNC machine is not a light machine. Therefore, have some help for lifting it onto a sturdy desktop or Spyder CNC stand.

The 1/8 ER11 collet comes on the spindle and the 1/4 ER11 collet can be found in the crate.

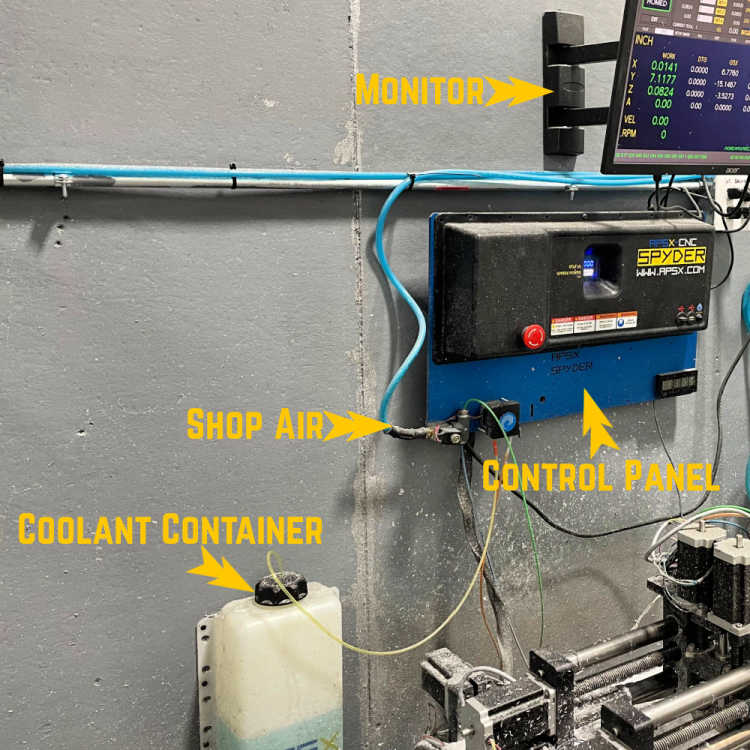

2 - Install the control panel and the monitor

The control panel and the monitor come with mounting kits for wall mounting. You can also buy the Spyder CNC Tower Stand to place the monitor and the control panel. The control panel must be mounted in a location so that the User may safely engage the Emergency-Stop switch while the machine is running.

3 - Connect the shop air and the coolant

Connect the monitor to the control panel with the VGA cable on the control panel.

The coolant container can be mounted on the wall. The tube end with the filter should be in the container, and the other end should be connected to the pump on the control panel. Spyder CNC consumes 1.35ml/min at average or 6.5ml/min at max. Add 90% tap water and 10% denatured alcohol into the container.

For mist generation, shop air and air hose with 0.25in female quick-connect coupler is required. We use the same air to cool the spindle down. Max PSI for air is 80-110. Air consumption rate is 2.5 CFM.