The Complete Desktop FIM Package

Go from CAD to Production in Hours Instead of Weeks. Digital tooling enabled by the xMOLD resin allows you to print real tools that are compatible with hundreds of actual injection molding materials. Print traditional molds for higher volume runs or dissolvable molds for 'impossible' geometries. Skip the machine shop, just hit print and go. Iterate more frequently and quickly. Cut tooling cost by 96%.

What's in the package?

APSX-PIM

MUD Base for xMOLD

XiP Desktop 3D Printer

xWASH FiM and Wash+Cure

xMOLD resin (5kg)

XiP build plate

Evercare Service Plan (1 year)

FREE Mold Generator Software (1 year)

.

For a brief video about the FIM and APSX-PIM, please click on here.

.

APSX-PIM Desktop Injection Machine

KEY FEATURES OF APSX-PIM

- Compact design (4 ft by 1 ft footprint)

- Maximum barrel temperature: 315 C (600 F)

- Wear resistant bronze barrel and case hardened steel plunger with hard chrome plating made in Ohio

- Maximum clamp force: 5 tons

- Maximum shot size: 30 cu-cm (1.83 cu-in)

- Injection pressure: 345 BAR (5000 PSI)

- Standard mold size: 6in X 4.8in

- Parts as large as 100 sq-cm (15 sq-in)

- All electric machine (110V)

Compact Size - Optimized Risk Control - Minimal Waste - Precision and Accuracy - Adaptability to Changing Requirements - Cost-Effective Performance - Time to Market Faster

APSX-PIM BROCHURE (PDF)

APSX-PIM BROCHURE (PDF)

.

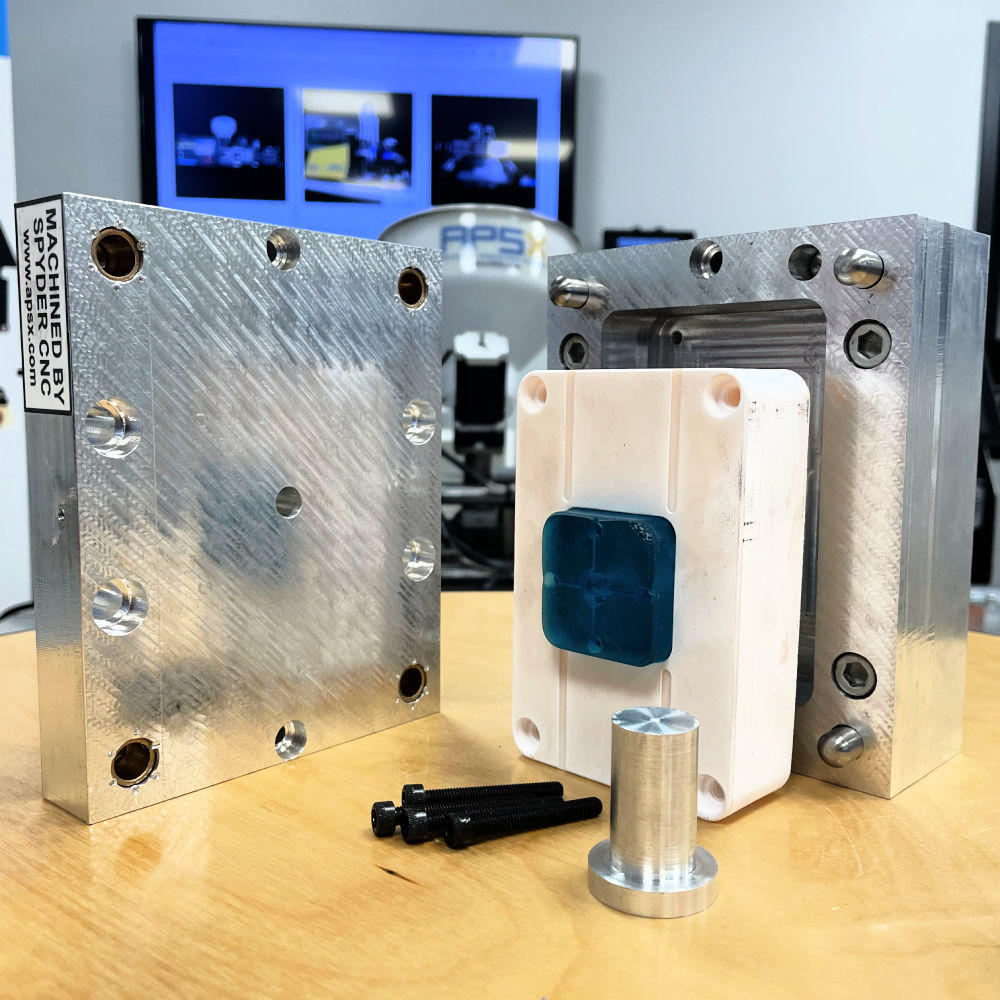

MUD Base for nexa3D xMOLD

KEY FEATURES OF MUD Base

- Standard size 6061 aluminum MUD base machined by the Spyder CNC for the nexa3D xMOLD Printed Molds.

- This mold comes with the bushings and pins installed.

- You just need to print your nexa3D xMOLD.

Here is the link to the instructional video: CLICK HERE .

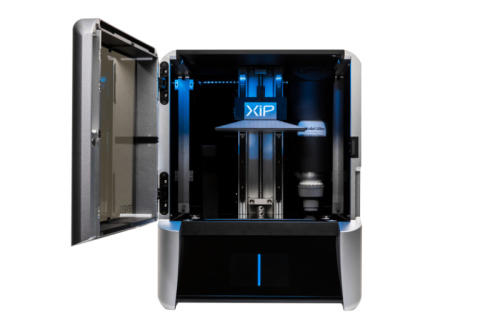

XiP Desktop 3D Printer

Ulrafast, compact production of 3D printed parts and tools.

KEY FEATURES OF XiP 3D PRINTER

- Print volume: 4.8 liters

- Build volume: 195 X 115 X 210 mm

- Pixel size: 52 microns

- Print speed up to 180 mm/hour

- Auto-dispensing of resin

- Heavy duty design

.

xWASH FIM

For rapid and safe dissolving of xMOLD 3D printed injection mold tooling.

KEY FEATURES OF xWASH

- Demolding at up to 85C for faster processing

- Agitation further speeds up the process

- Capacity of 46.2 liters allows for processing of large batches

.

Wash + Cure

A two in one workstation for compact operations.

KEY FEATURES OF Wash and Cure

- Washing of loose parts

- Washing with stirring for maximum effect

- Curing on turn table for even application of UV light

- 405 nm wavelength for compatibility with most resins

xMOLD resin

The most versatile 3D printed injection mold tooling resin.

KEY FEATURES OF xMOLD

- Withstands up to 400C

- Soluble, for maximized mold design freedom while enabling unlimited part complexity

- Low stick for easy mechanical seperation

- Machinable for easy post processing

All components of the APSX-PIM are made in Cincinnati, OH USA.

Showroom meeting is available with appointment. Please SCHEDULE a call or showroom demo day.

.:. Dream. Design. Make NOW. .:.

Watch APSXYouTube | - | Schedulea Visit or Call | - | APSX-PIMUser Guides |

| - |  | - |  |

DO YOU NEED FINANCING?

moirons, minijector, formlabs, arburg, all3dp, fictiv, micro-molder, abplasticinjectors, babyplast, boymachines, mediummachinery, techkits