Introduction

In the world of precision machining, CNC (Computer Numerical Control) lathes are indispensable tools for manufacturing a wide range of components. Two popular types of CNC lathes are Swiss CNC lathes and regular CNC lathes. In this blog, we'll delve into the key differences between these two lathe types and compare the APSX-NANO, a Swiss CNC lathe, with a HAAS regular CNC lathe.

Swiss CNC Lathe: APSX-NANO

The APSX-NANO is a Swiss CNC lathe known for its precision and ability to create intricate and small parts. This type of lathe is particularly suited for producing small and complex components with tight tolerances such as ejector pins for injection mold tools, custom screws, custom pins, flat parts (live tool), aerospace, medical, drone and firearm parts. Here are some features and advantages of the APSX-NANO:

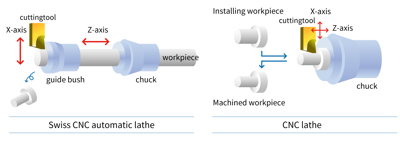

Guide Bushing: Swiss CNC lathes like the APSX-NANO utilize a guide bushing, which provides excellent support to the workpiece, minimizing vibration and ensuring precise machining. This feature is crucial when working with small, delicate and long parts.

Material Feeding: In Swiss CNC lathes, the material is fed through a guide bushing, allowing for the creation of long and slender parts with exceptional precision. The ability to work with bar stock efficiently is a distinct advantage.

Tooling Setup: The APSX-NANO allows for quick tool changes, reducing downtime between setups and enhancing overall productivity. It also offers two live tools for extra versatility.

Regular CNC Lathe: HAAS

HAAS is a well-known manufacturer of regular CNC lathes. These machines are versatile and widely used in a variety of industries for both small and large-scale production. Let's examine the key features and advantages of a HAAS CNC lathe:

Chucking: Regular CNC lathes use chucks to hold the workpiece, which is different from the guide bushing used in Swiss CNC lathes. This chucking system is suitable for a wide range of part sizes and shapes.

Material Handling: HAAS lathes can handle a broader spectrum of materials, making them a preferred choice for general machining applications. They are not limited to bar stock and can work with castings, forgings, and more.

Tool Capacity: Regular CNC lathes often have a higher tool capacity, allowing for more tooling options during the machining process. This is advantageous for complex part production.

Simplicity: HAAS lathes are generally considered more straightforward to operate and set up compared to Swiss CNC lathes. They are a better choice for shops that need versatility and ease of use.

Choosing the Right Lathe

The choice between a Swiss CNC lathe like the APSX-NANO and a regular CNC lathe like HAAS depends on your specific machining needs. Consider the following factors when making your decision:

Part Complexity: If you primarily work with intricate, small parts, a Swiss CNC lathe may be the better choice.

Material Variety: If your machining tasks involve a wide range of materials, a regular CNC lathe may be more versatile.

Tooling Requirements: Assess your tooling needs and the number of tools required for your projects. This will help determine whether a regular or Swiss CNC lathe is more suitable.

Production Volume: Consider the volume of parts you need to produce. For high-volume production, a regular CNC lathe may be more efficient, while Swiss CNC lathes excel at small-batch and precision work.

Conclusion

Both Swiss CNC lathes like the APSX-NANO and regular CNC lathes like HAAS have their own set of advantages and applications. The choice between them ultimately comes down to your specific machining needs and production requirements. By understanding the key differences and features of each type, you can make an informed decision and select the lathe that best suits your manufacturing operations.