In the competitive landscape of product design, speed and efficiency are key. This blog delves into how in-house CNC machining and injection molding can transform your production process.

Here is the link to the YouTube video.

Unleashing Speed and Efficiency in Product Design with CNC Machining and Injection Molding

In the fast-evolving field of product design, the ability to swiftly adapt and execute is paramount. Companies across the globe are turning towards more integrated manufacturing solutions to stay competitive. In particular, in-house CNC machining and injection molding are becoming pivotal in transforming production processes. This article explores the significant advantages of these techniques, as outlined in a detailed video presentation by APSX LLC.

The Role of CNC Machining in Modern Manufacturing

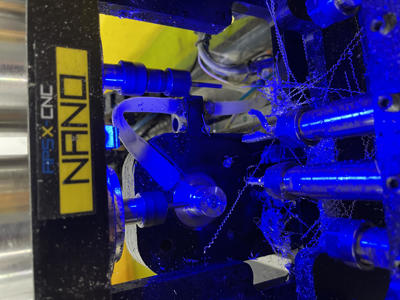

CNC (Computer Numerical Control) machining stands out for its precision and flexibility. It allows for the automated control of machining tools by means of a computer, which interprets geometric data to operate complex machinery. This method is particularly advantageous for its ability to produce parts with high precision and to quickly adapt to design changes without the need for extensive downtime or retooling.

CNC machining is not just about maintaining accuracy; it's also about agility. Rapid prototyping is feasible with CNC machines, which enables designers and engineers to refine designs and test functionalities faster than ever before. This speed in prototyping is crucial for iterative design processes, allowing for quick feedback and adjustments that ensure the final product meets the exact needs of the market.

Enhancing Production with Injection Molding

Alongside CNC machining, injection molding is a core component of in-house manufacturing that enhances production capabilities. This process involves injecting molten material into a mold to produce parts with high uniformity and excellent material properties. Injection molding is particularly valued for its ability to produce high volumes of parts with consistent quality, which is essential for mass production.

The integration of injection molding in-house allows companies to drastically reduce the production cycle times. With molds that can be used repeatedly for tens of thousands of cycles, manufacturers can achieve substantial cost savings over time. Additionally, having control over the injection molding process in-house ensures greater quality control and reduces the dependency on external suppliers.

Strategic Advantages of In-House Production

By adopting in-house CNC machining and injection molding, companies gain several strategic advantages. The most significant is the reduction in turnaround times from design to production. This rapid production capability enables companies to respond more effectively to market demands and reduces the time it takes to introduce new products to the market.

Furthermore, in-house production affords companies a higher degree of control over the entire manufacturing process. This control can lead to better quality products and more efficient use of resources, which in turn results in cost savings. Additionally, by reducing the need to coordinate with multiple suppliers and manufacturers, companies can simplify their supply chains, reducing potential disruptions and further enhancing efficiency.

Conclusion

As demonstrated in the video presentation, incorporating CNC machining and injection molding into in-house production setups offers compelling benefits for companies looking to improve their product design and manufacturing processes. These technologies not only foster efficiency and speed but also enhance the overall quality and economic viability of products. Companies that invest in these capabilities are well-positioned to lead in the competitive landscape of product design and manufacturing.

For more insights and detailed case studies, watch the full video on [APSXLLCYouTubeChannel] and discover how these technologies can revolutionize your production process.

#ProductDesign #CNCMachining #InjectionMolding #Manufacturing #Efficiency #apsxllc #apsxpim #apsxnano #3dprinting