In the dynamic manufacturing realm, innovations often redefine conventional processes, leading to improved outcomes and enhanced efficiency. One such transformation can be observed in overmolding applications, where the APSX-PIM injection molding machine challenges the traditional myth associated with vertical injection molding machines. Let's explore how the APSX-PIM is changing overmolding by offering a new approach and efficient solution.

Rethinking Overmolding with the APSX-PIM

Historically, vertical injection molding machines have been the go-to choice for overmolding applications. The reasoning behind this preference lies in the idea that gravity assists in ensuring seamless adhesion of the overmolded material to the existing substrate.

Introducing the APSX-PIM: A New Overmolding Paradigm

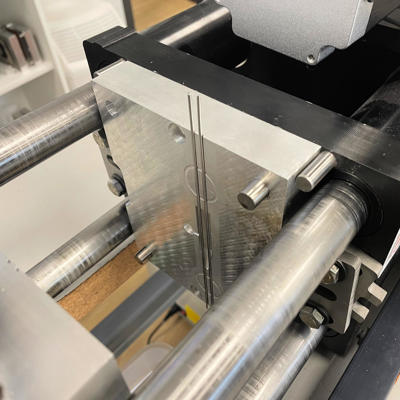

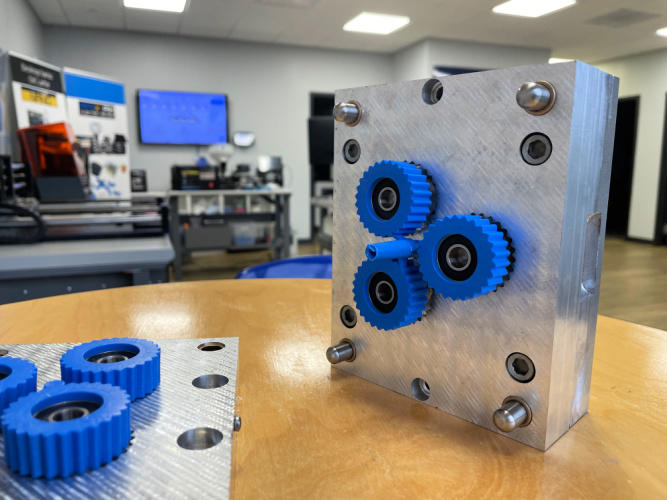

The APSX-PIM, an innovative horizontal injection molding machine, has emerged as a transformative solution for overmolding applications. Unlike traditional vertical machines, the APSX-PIM introduces a fresh perspective, addressing the shortcomings and inefficiencies of the conventional approach. The APSX-PIM suggests using magnets behind the mold to hold the overmolded metals. The user can place the metal parts in specifically designed slots because the magnets behind them are strong enough to hold them precisely. For plastic parts, a snapping mechanism can be used instead of magnets.

Advantages of the APSX-PIM for Overmolding

- Versatile Design: The horizontal configuration of the APSX-PIM allows for more flexible mold designs and adaptability, accommodating diverse overmolding projects.

- Space Efficiency: The compact footprint of the APSX-PIM optimizes floor space in manufacturing facilities, contributing to a more efficient workspace layout.

- Simplified Maintenance: The modular design of the APSX-PIM streamlines maintenance procedures, minimizing downtime and ensuring consistent production.

- Cost-Effective Operation: APSX-PIM's cost-effectiveness in terms of initial investment and ongoing operational expenses positions it as an attractive option for various business scales.

Illustrating the APSX-PIM Approach to Overmolding

Consider a scenario where an ergonomic plastic grip needs to be overmolded onto a metal part. The APSX-PIM's approach to this process is outlined below:

Material Selection: Choose compatible materials for the metal part and the overmolded grip, considering material compatibility, adhesion, and desired properties.

Mold Design: Develop a mold design that accommodates the metal part and integrates necessary injection channels. The horizontal orientation of the APSX-PIM facilitates straightforward mold designs.

Injection Process: Load the selected materials into the APSX-PIM's hopper. Configure injection parameters like temperature, pressure, and cycle time based on material specifications.

Injection and Cooling: The APSX-PIM injects the molten plastic material over the metal part. The horizontal setup promotes uniform material distribution and efficient cooling.

Completed cycle: After the overmolded part solidifies, the mold opens, and the finished product can be picked up.

The APSX-PIM's novel approach to overmolding showcases its advantages over traditional vertical injection molding machines. Through its horizontal design, simplified maintenance, and cost-effective operation, the APSX-PIM demonstrates how it can streamline overmolding processes.

Conclusion

The APSX-PIM challenges the status quo by offering a fresh outlook on overmolding, countering the notion that vertical injection molding machines are the sole solution. As industries evolve, embracing such advancements can lead to a more streamlined, adaptable, and cost-efficient overmolding process.