A user guide for fixturing jigs and wokholding on Spyder CNC

|

| -Click to Go Back |

Spyder CNC Machine comes with a base plate with 2 inches apart 1/4-20 threaded holes. You need to fixture your workpiece on it. We provide a setup jig to use under the workpiece that you will be milling. Your other options are to use a vise or double sided tape for light milling.

Loading the g-code to the Spyder CNC

- Insert the USB stick where you have the g-code file onto the control panel's USB port.

- Go to the FILE tab on the user screen

- Click on the file on the left side (USB stick) and click on the COPY button to move it to the .ngc working folder

- Click on the file in the working folder and double-click or click on the LOAD g-code button to open it in the g-code window

- If you need to edit the file, go to the EDIT tab, edit and then SAVE

- You can look at the file in the PLOT tab to see how it looks in perspective view

Here is a video below that shows each step involved in this process:

.

Tool touch off

- Mount the setup jig after tapping the mounting holes.

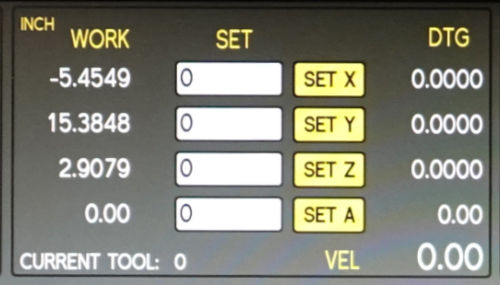

- To define the work coordinates (G54 work offsets), enter ZERO or your own value and click on the SET X button by manually moving the tool to touch the workpiece from X direction. Repeat this process for the Y axis. It is better to use the pendant controller for the final movements during the touch off.

- Z touch off: Use the pendant and a piece of paper until the tool releases the paper. Although the paper is about 0.006 inches thick, we use 0.010 inches for the Z offset value

| - |  | - |

Run the g-code program

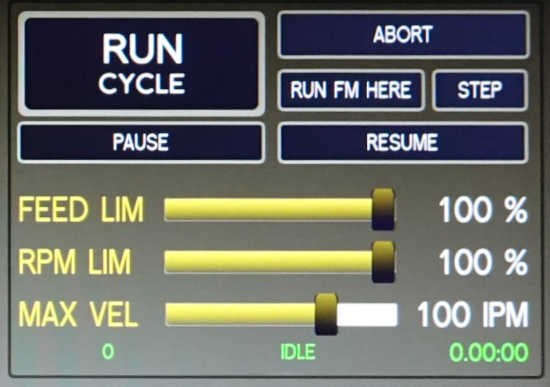

- Click on RUN CYCLE on the screen or hit the R button on the keyboard to start the program.

- It will go to "tool change position" first. If you already have the tool installed on it, it will move on.

- Once the program is completed, it will stop and wait.

|

Workholding methods

- Setup jig: You can make your own setup jig (spoil board) or use the setup jig we provide. You can cut through the setup jig. You can also go all the way around the workpiece without flipping it over.

- Precision vise: You can use a vise by mounting it to the hole pattern on the base. If you do not mill the same part repeatedly, it may make sense to use a vise.

- Double sided tape or vacuum table: If your workpiece is a type of sheet plate or if it is a very light milling, it may make sense to use a high-strength double-sided tape. First, clean the surface with alcohol. Next, align your workpiece and press firmly on the tape. You need to add the thickness of the tape for the z offset. Or a custom vacuum table can be an option. You need to customize a vacuum table or you need to make your own.